Volleyball Court PVC Sports Flooring Volleyball Court Pvc Sports Flooring,Mat Flooring For Volleyball,Pvc Volleyball Mat Flooring,Indoor Volleyball Court Flooring Jiangsu Ruidong Sports Technology Co., Ltd , https://www.cnruidongsports.com

Cleaner, Safer, and More Efficient: How Magnetic Filtration is Used in Different Industries

In recent years, the application of magnetic filtration has become increasingly common across various industries, such as aerospace, automotive, and food processing. Magnetic filtration involves using magnetic fields to extract ferrous particles from liquid streams, ensuring cleaner and more efficient operations.

This method is not only cost-effective but also highly efficient in removing metallic debris during industrial processes. In the following sections, we’ll take a closer look at how magnetic filtration enhances both process efficiency and product quality in different sectors.

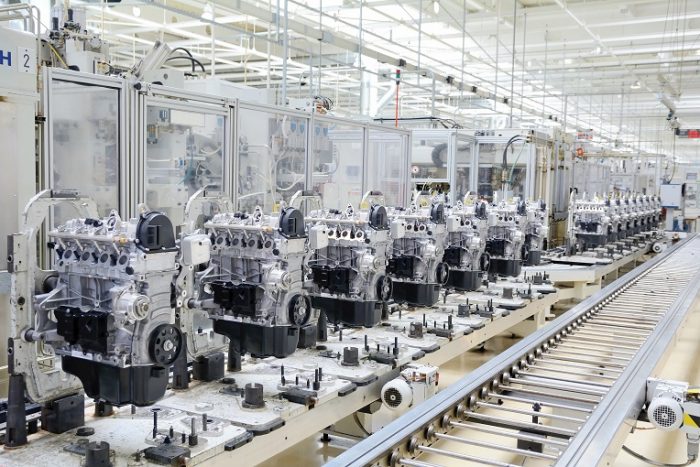

**Automotive Industry**

Magnetic filtration plays a crucial role in the automotive sector by purifying oil, coolant, and fuel systems. It’s widely used in engine oil filtration, where magnetic filters capture metallic particles, extending the life of engine parts and reducing mechanical wear. This leads to better engine performance and reliability.

Additionally, these filters are essential in fuel systems, where they remove contaminants that could otherwise damage the engine or reduce fuel efficiency. In coolant systems, magnetic filtration helps eliminate metal debris, which can cause corrosion and lead to overheating or engine failure.

**Aerospace Industry**

In the aerospace industry, magnetic filtration is vital for maintaining the integrity of critical systems like hydraulics, fuel, and lubrication. Magnetic filters are used to remove ferrous particles from hydraulic fluids, preventing damage to sensitive components and potential system failures.

Similarly, in fuel systems, magnetic filtration helps protect engines from contamination, ensuring optimal performance and fuel efficiency. Lubrication systems also benefit from this technology, as it removes metallic debris that could cause excessive wear on aircraft engines and other mechanical parts.

**Food Processing Industry**

The food processing industry relies heavily on magnetic filtration to ensure product safety and quality. It is commonly used to remove metal particles from food items, preventing contamination and ensuring compliance with strict food safety standards.

These filters are especially useful in handling dry ingredients like sugar, flour, and cocoa powder, where even small metal fragments can pose a risk. Additionally, magnetic filtration is applied in beverage production, such as beer and wine, to remove metallic debris and maintain product freshness and quality.

By integrating magnetic filtration into their processes, industries can significantly improve operational efficiency, reduce maintenance costs, and enhance the overall quality of their products. Whether in cars, planes, or food factories, this technology continues to prove its value in modern manufacturing.