Roller Skate Wooden Floor,Roller Skating Court Floor,Roller Skating Room Sports Floor,Roller Skating Room Wooden Floor Jiangsu Ruidong Sports Technology Co., Ltd , https://www.cnruidongsports.com

Cleaner, Safer, and More Efficient: How Magnetic Filtration is Used in Different Industries

In recent years, the use of magnetic filtration has become increasingly common across various industries such as aerospace, automotive, and food processing. Magnetic filtration is a method that uses magnetic fields to extract ferrous particles from liquid streams, ensuring cleaner and safer processes.

This technique is not only cost-effective but also highly efficient in removing metallic debris throughout industrial operations. In the following sections, we will look at how magnetic filtration contributes to improving process efficiency and product quality in different sectors.

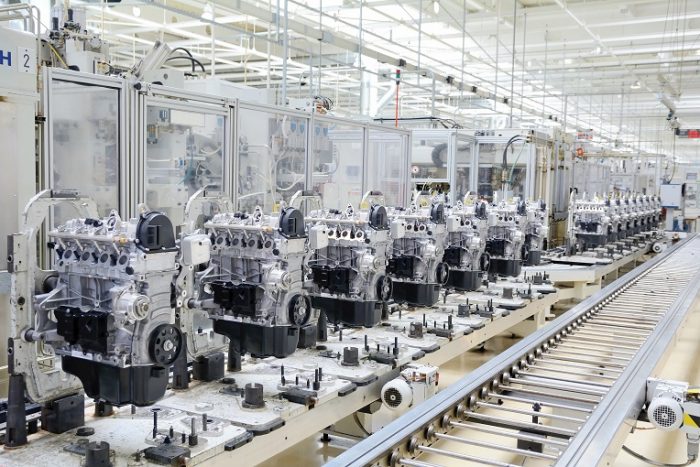

**Automotive Industry**

Magnetic filtration plays a vital role in the automotive industry, especially in maintaining the cleanliness of oil, coolant, and fuel systems. One of the most common applications is in engine oil filtration, where magnetic filters capture metal shavings and other ferrous particles. This helps extend the life of engine components, reduces wear, and enhances overall engine performance.

Additionally, magnetic filters are used in fuel systems to remove contaminants that could otherwise damage the engine or reduce fuel efficiency. They are also employed in coolant systems to eliminate metallic debris, which can lead to corrosion and potentially cause engine overheating or failure.

**Aerospace Industry**

In the aerospace sector, magnetic filtration is essential for maintaining the reliability and safety of critical systems. It is widely used in hydraulic systems, fuel systems, and lubrication systems to remove ferrous debris.

By filtering out metallic particles from hydraulic fluid, magnetic filters help prevent damage to sensitive components and avoid system failures. Similarly, in fuel systems, magnetic filtration ensures that no harmful particles enter the engine, protecting it from potential damage and maintaining optimal fuel efficiency.

Lubrication systems also benefit from magnetic filtration, as it removes metallic debris that could cause excessive wear on engine parts, ultimately contributing to longer-lasting and more reliable aircraft systems.

**Food Processing Industry**

In the food processing industry, magnetic filtration is crucial for ensuring the safety and quality of food products. It is commonly used to remove metal particles, such as iron or steel fragments, from ingredients like sugar, flour, and cocoa powder. This helps prevent contamination and maintains the integrity of the final product.

Moreover, magnetic filtration is applied in beverage production, including beer and wine, to eliminate metallic debris that could affect taste, clarity, and shelf life. By implementing this technology, food manufacturers can meet strict safety standards and provide consumers with high-quality, contaminant-free products.

Overall, magnetic filtration is an essential tool in modern industrial processes, offering a reliable and efficient way to maintain clean systems and ensure product quality across multiple sectors.