VZÚ Plzeň, a leading robotic inspection service provider, is transforming the way power generation sites are inspected in the Czech Republic by leveraging the advanced capabilities of the Elios 3 drone. Safety The Elios 3 enables VZÚ Plzeň to safely inspect complex and hazardous areas in power plants, such as high places and confined spaces. This eliminates the need for scaffolding or rope access technicians, allowing inspections to be conducted from a safe distance. Efficiency Using the Elios 3, VZÚ Plzeň completed inspections of 16,000 points of interest in just 10 days during scheduled downtime. The speed and accuracy of the drone allowed them to deliver timely results, improving overall project timelines. Accuracy Even when inspecting structures over 100 meters tall, the Elios 3 provides precise data that can be localized, ensuring accurate identification of potential issues. This helps maintenance teams target their efforts effectively and efficiently. Business Growth VZÚ Plzeň has expanded its client base and secured new projects by offering detailed asset inspections using the Elios 3. Their high-quality data and insights have set them apart in the competitive NDT market, delivering more value to their clients. Non-Destructive Testing (NDT) is a method used to evaluate the condition of materials, components, or structures without causing damage. It plays a critical role in industries like power generation, where safety and reliability are paramount. By using NDT, engineers can detect flaws, assess wear, and ensure assets remain in optimal working condition, preventing costly failures and downtime. VZÚ Plzeň has embraced cutting-edge technologies like the Elios 3 to enhance its NDT capabilities across power generation sites in the Czech Republic. After participating in a Flyability training program in Lausanne, they initially used the Elios 2 for aerial and confined space inspections. Now, they have upgraded to the Elios 3, which has significantly improved their operations. Filip Schmidt, VZÚ Plzeň’s lead drone inspector, noted, “The Elios 3 has made our operations much smoother. We’ve seen improvements in piloting, defect localization, data collection, and overall flight efficiency.†Initially, some industry professionals were skeptical about the benefits of drone-based inspections. However, VZÚ Plzeň demonstrated the value of the Elios 3 through consistent, high-quality results that reduced costs, saved time, and improved safety. This has helped build a strong reputation among their clients. Boiler inspections often require extensive scaffolding and pose significant safety risks. With the Elios 3, VZÚ Plzeň can quickly gather visual and LiDAR data from inside the boiler without any physical access. This not only saves time but also reduces the risk to inspectors and avoids unnecessary costs associated with scaffolding and labor. If no maintenance is needed, the plant can avoid all related expenses. If repairs are required, the exact location of the issue is identified, enabling targeted and efficient maintenance work. This boiler inspection was done using the Elios 3 to access the asset from the inside VZÚ Plzeň faced a unique challenge when inspecting flue gas ducts, which are prone to wear due to abrasive particles. At one site, steel guiding plates had been installed to protect the system, but they were found to be eroded in certain areas. Rope-access inspections were no longer feasible, making the Elios 3 the ideal solution. The drone was able to navigate the dangerous environment and identify critical defects, providing essential data without risking human safety. This approach offered a safer and more efficient alternative to traditional methods. The Elios 3 makes it possible to inspect assets at height from a safe location on the ground In 2023, VZÚ Plzeň was tasked with inspecting the cooling towers of a power plant. They conducted two inspections over four months, aligning with planned downtimes. Using the Elios 3, they successfully inspected 16,000 points across four cooling towers in just 10 days. The cooling tower bases had many structures that were inspected with the Elios 3 With such a large amount of data collected, VZÚ Plzeň ensured accurate analysis by identifying and localizing defects within the model. This provided clear visualizations and detailed assessments for plant managers, helping them make informed decisions about maintenance and repairs. VZÚ Plzeň's success with the Elios 3 has shown the immense value of drone-based inspections in the power generation sector. By eliminating the need for costly scaffolding and reducing safety risks, they have improved both operational efficiency and worker safety. “Our journey into drone inspections has transformed how we operate and how our clients perceive safety and efficiency,†said Filip Schmidt. “We are committed to delivering excellence in every mission, continuously exploring new possibilities in the power generation space.†VZÚ Plzeň is now conducting NDT inspections across the Czech Republic, helping clients achieve significant savings through faster, safer, and more accurate inspections. As they continue to expand, they look forward to applying the Elios 3 in more challenging environments, further proving the effectiveness of drone technology in industrial settings. Learn more about the Elios 3 and its applications in power generation today. Plastic Fastener,Plastic Locking Clips,Plastic Snap Clips,Plastic Panel Clips Ningbo Hinix Hardware Industry & Trade Co., Ltd , https://www.hinixpack.comRevolutionizing NDT Inspections in Power Generation with the Elios 3

Key Benefits at a Glance

What is NDT?

Integrating NDT with Robotic Inspection

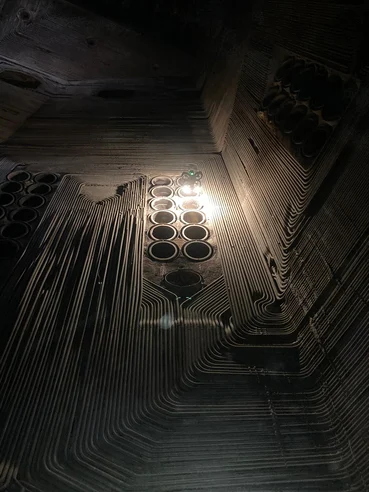

Streamlining Boiler Inspections

Inspecting Flue Ducts Safely

Completing Over 300 Flights in a Cooling Tower

Building Confidence in Drone Inspections