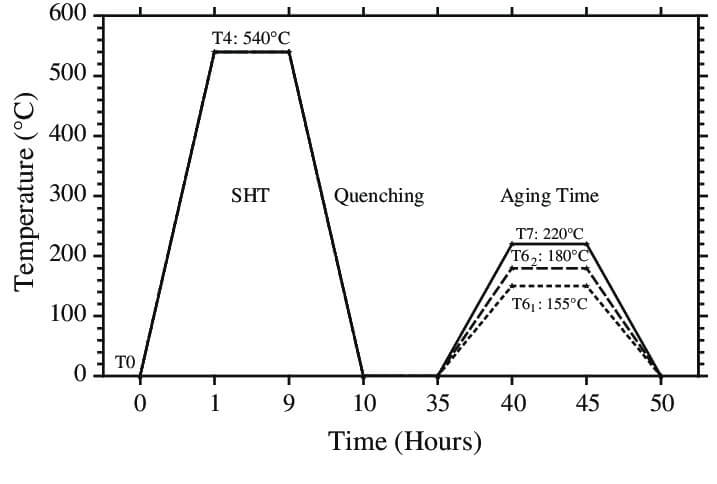

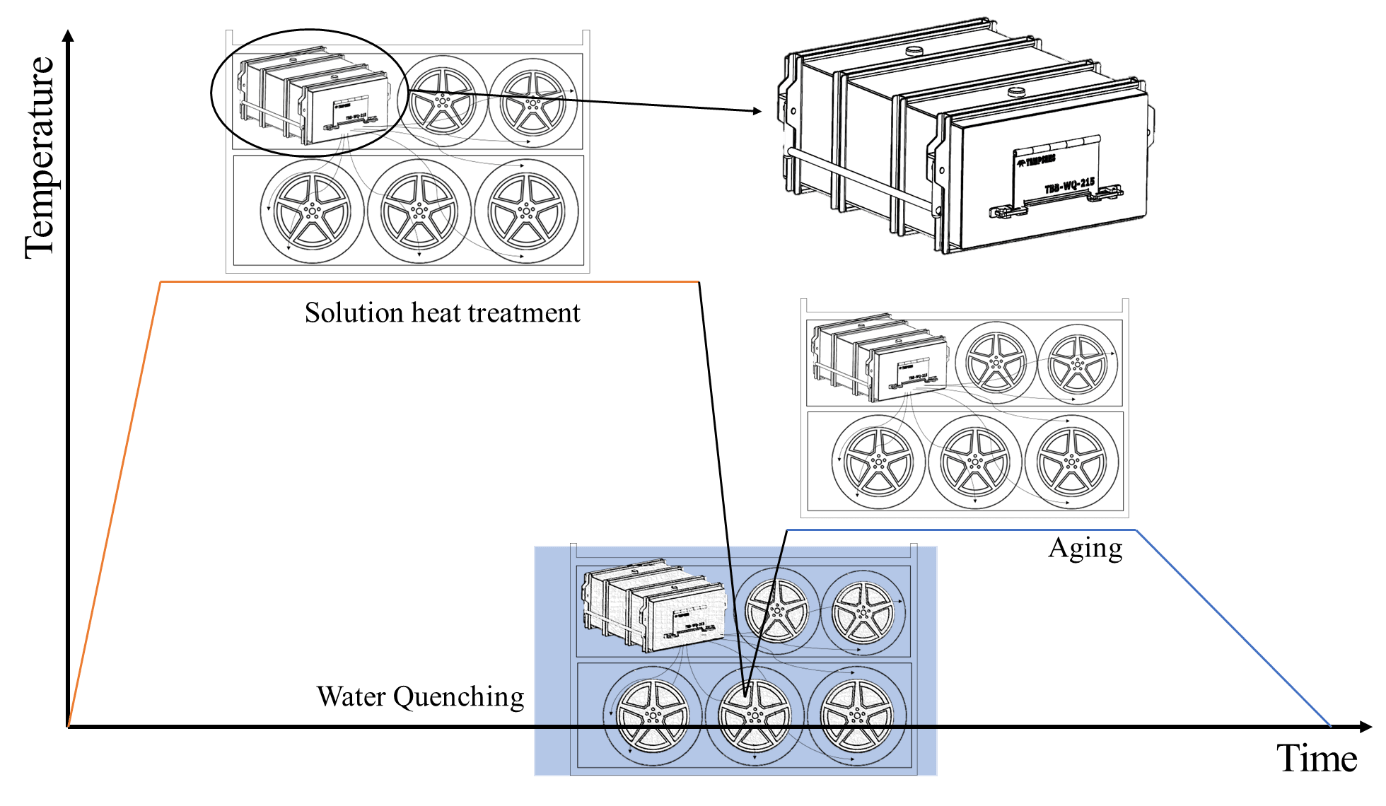

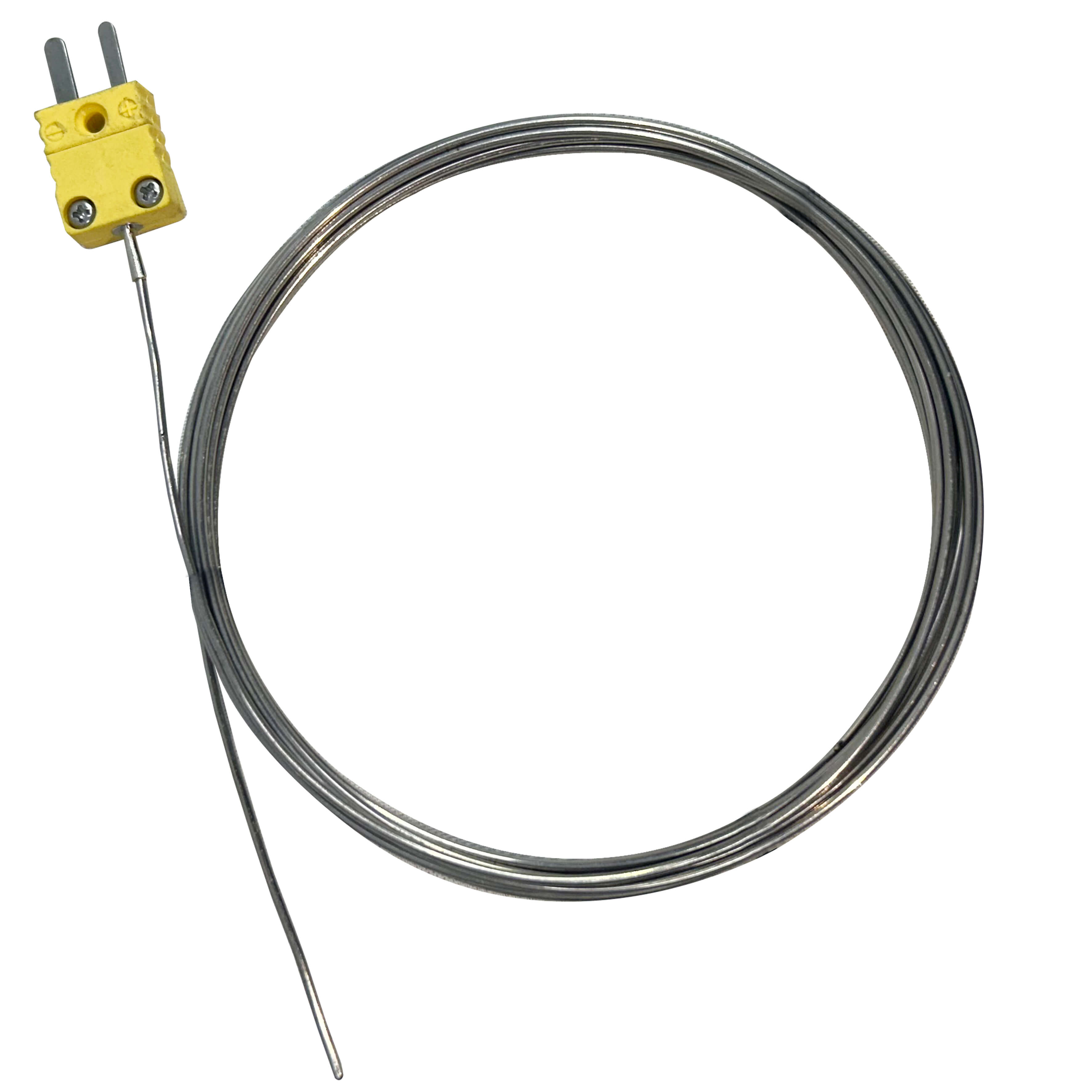

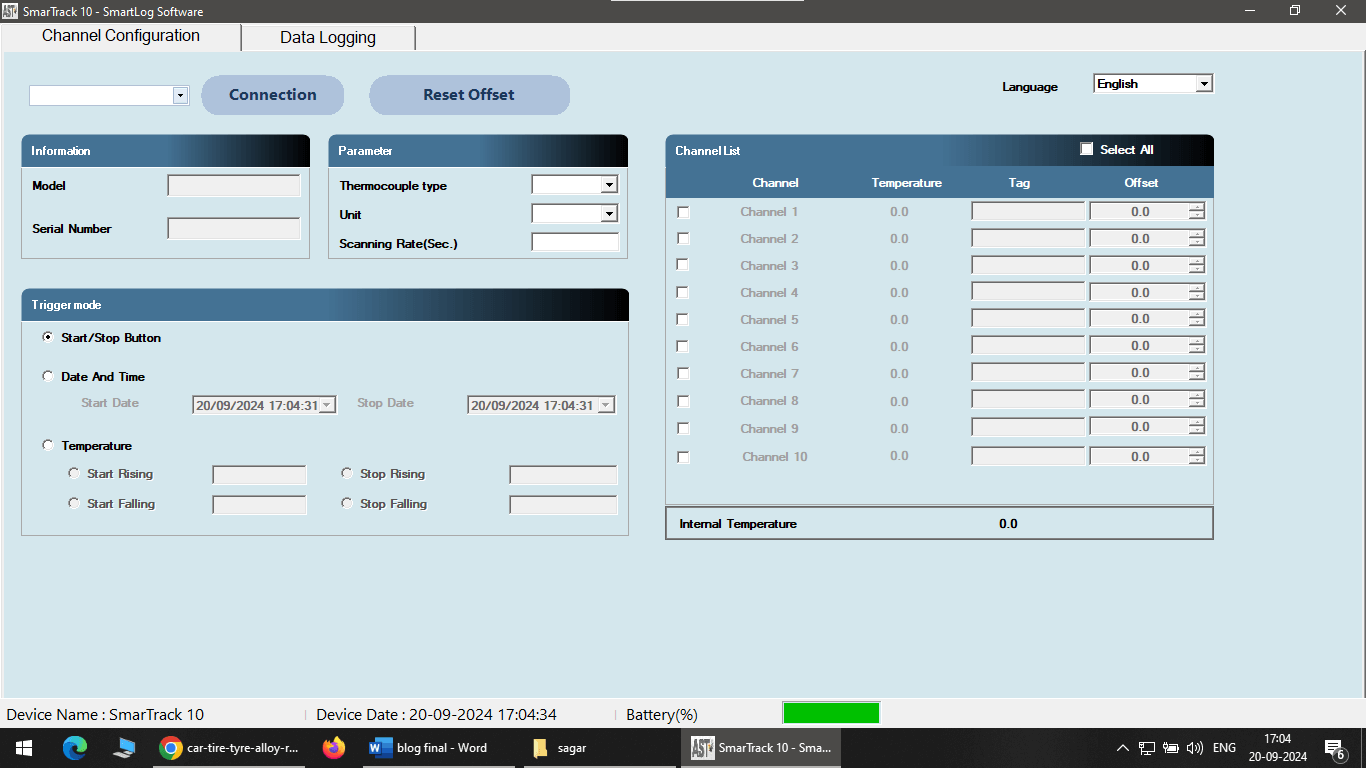

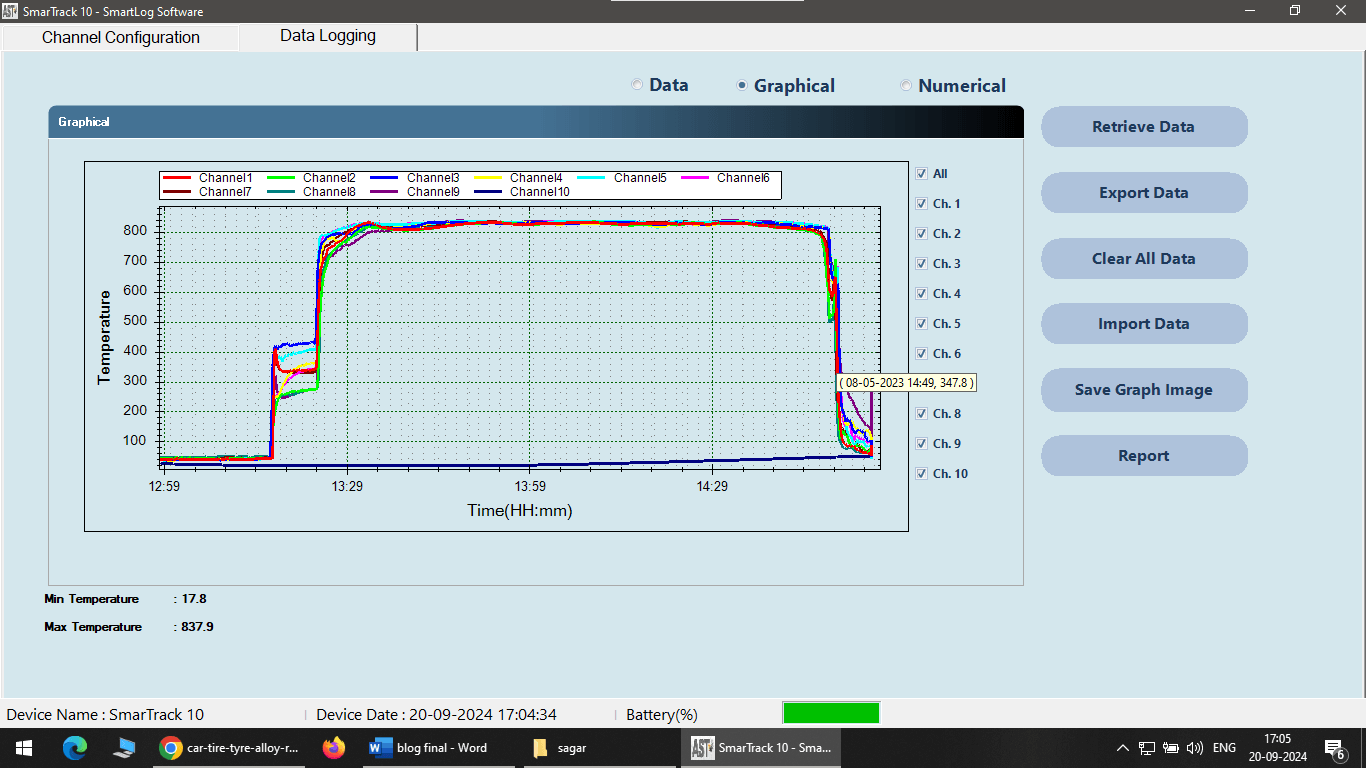

Aluminum heat treatment is a vital process that enhances the mechanical and physical properties of aluminum alloys, making them stronger, harder, and more durable. This process involves carefully controlled heating and cooling to achieve the desired material characteristics. Two of the most widely used methods are T6 and T7, which include key steps such as solution heat treatment, quenching, and aging. The T6 process consists of three main stages: The T7 process is similar to T6 but includes an additional or modified aging step, designed to improve the material’s stability at higher temperatures and increase resistance to stress and distortion. Quenching and aging are critical steps in achieving the final mechanical properties of aluminum alloys. If quenching is not done properly, it can lead to warping, cracking, or residual stresses. On the other hand, correct aging ensures that the alloying elements precipitate correctly, resulting in improved strength and durability. Precise temperature control is essential during heat treatment, especially during the quenching phase. Traditional methods often fail to provide complete and accurate data, leading to inconsistencies. This is where the Thermal Profiling System from Tempsens makes a significant difference. Tempsens’ Thermal Profiling System uses a Thermal Barrier Box (TBB-WQ-215), a data logger, and thermocouples to monitor temperature in real-time throughout the T6 or T7 process. This system ensures accuracy and reliability, reducing the risk of defects and enhancing overall performance.      Key Features: Tempsens provides advanced thermal profiling software that delivers deep insights into the heat treatment process. By monitoring the quench curve, manufacturers can ensure even cooling rates, reducing the risk of distortion, cracking, or residual stress. This precision helps achieve consistent mechanical properties like hardness and tensile strength. With advanced components like the TBB-WQ-215 thermal barrier box, Tempsens’ Thermal Profiling System ensures accurate temperature control, minimizing defects and maximizing product quality. Whether you're performing T6 or T7 heat treatments, adopting thermal profiling can boost efficiency, validate processes, and enhance material performance. Truss Type Automatic Production Line

Truss Type Automatic Production Line

The integration of the truss

mechanical arm and lathe bed enhances the compactness and aesthetic

appeal of the machine tool, enabling more stable and efficient automated

production. Each standard machine

tool is equipped with interfaces for truss automation, including

columns, protective features, and electrical components, which

facilitate easy installation of automation systems at a later stage. By

mounting the truss column onto the lathe bed, a stable integration is

achieved, unaffected by variations in the foundation or any

displacements. The planning and

design of the system incorporate a low truss height, a low center of

gravity, and ensure smooth and stable operation.

Truss Type Automatic Production Line,Automated Truss Production Line,Fully Automated Truss Production Line,Automation Truss Structure Production Line Ningbo Yien Machinery Co., Ltd , https://www.yienmachinery.com

T6 and T7 Heat Treatment Processes

The Importance of Quenching and Aging

The Role of Thermal Profiling Systems in Heat Treatment

How Thermal Profiling Improves Quenching and Aging

Benefits of Thermal Profiling

Software for Data Analysis and Temperature Monitoring

How Thermal Profiling Improves Quenching Accuracy