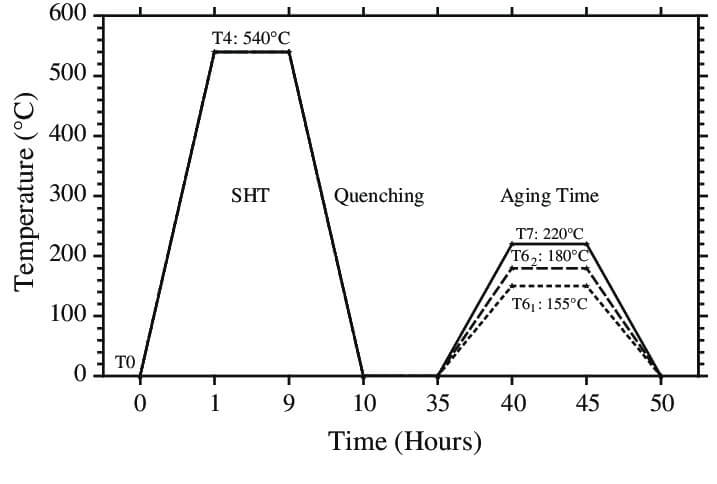

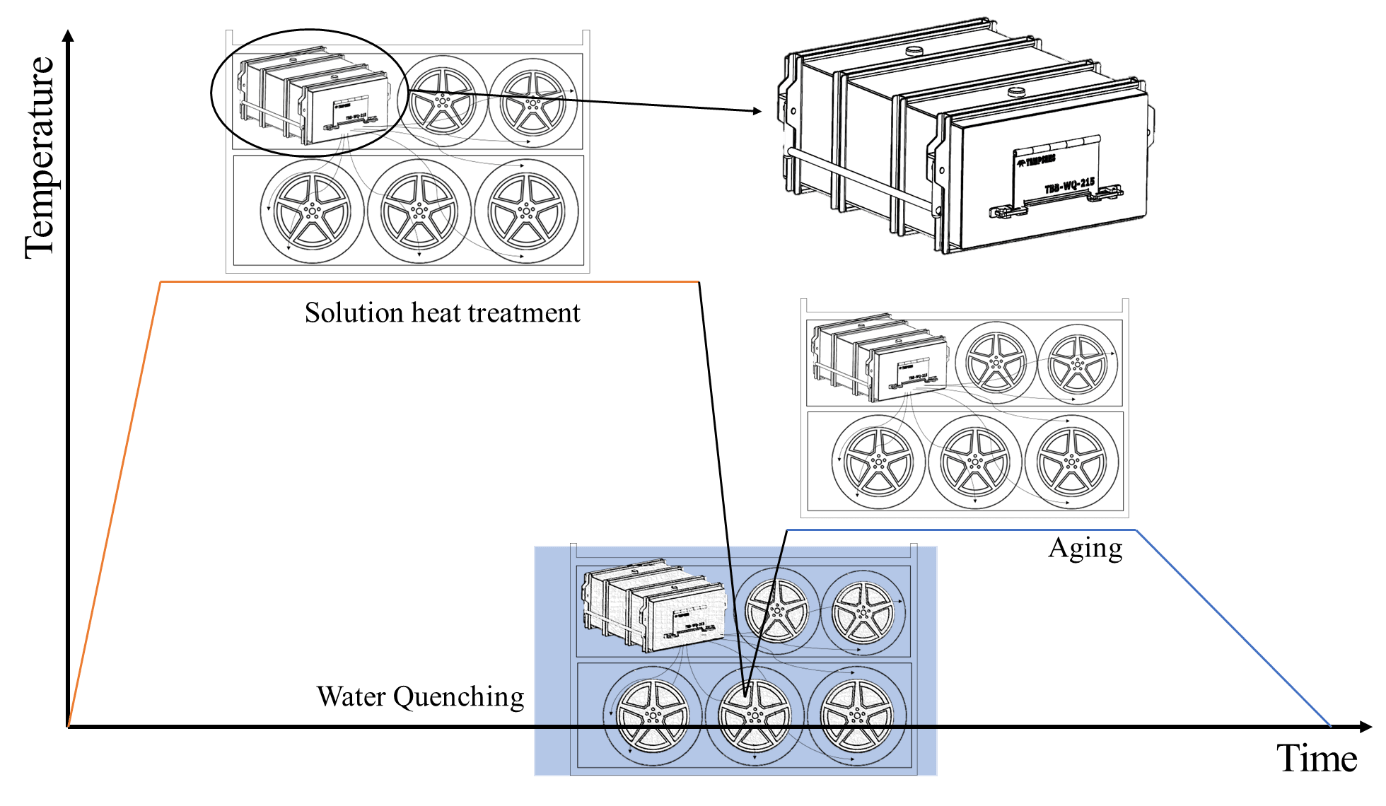

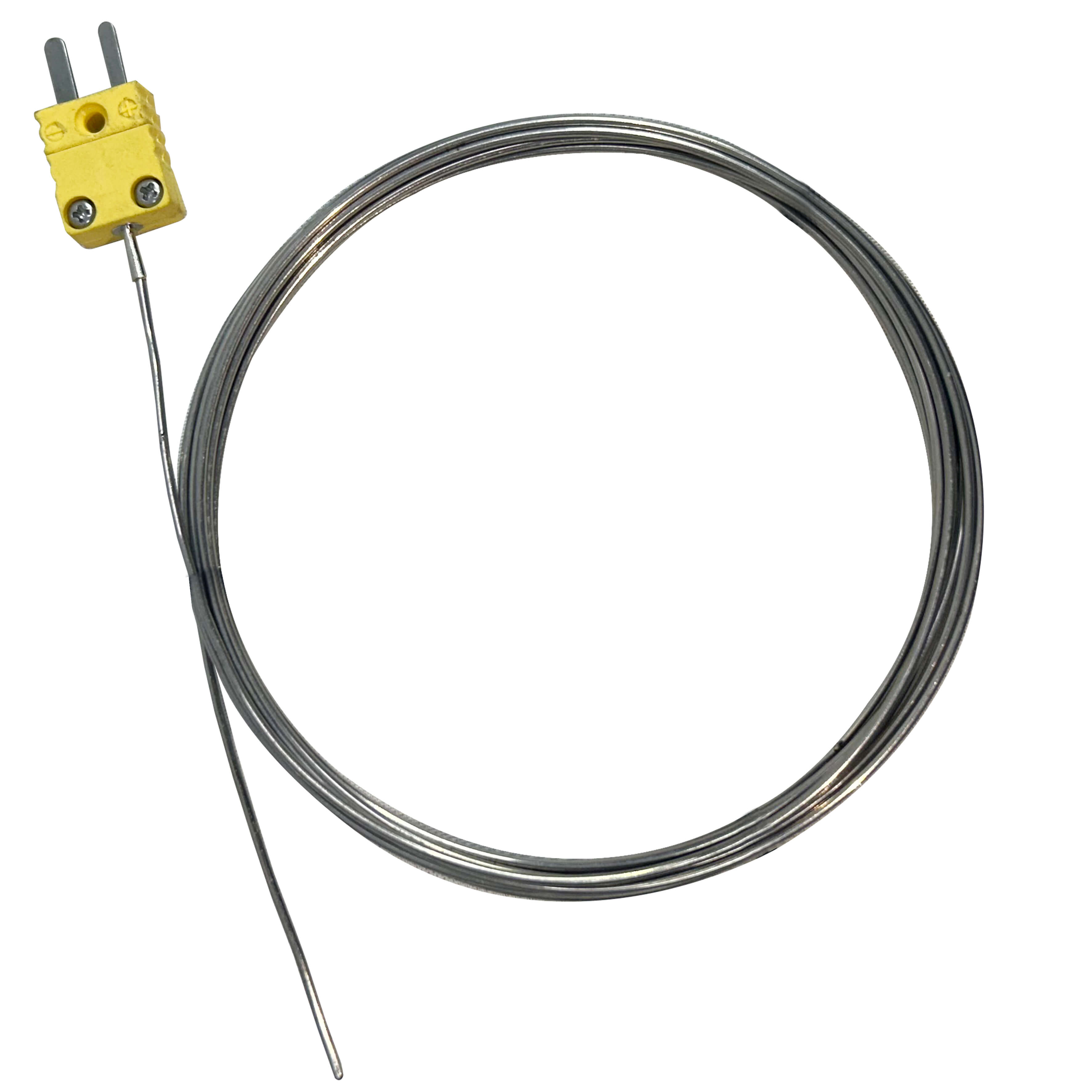

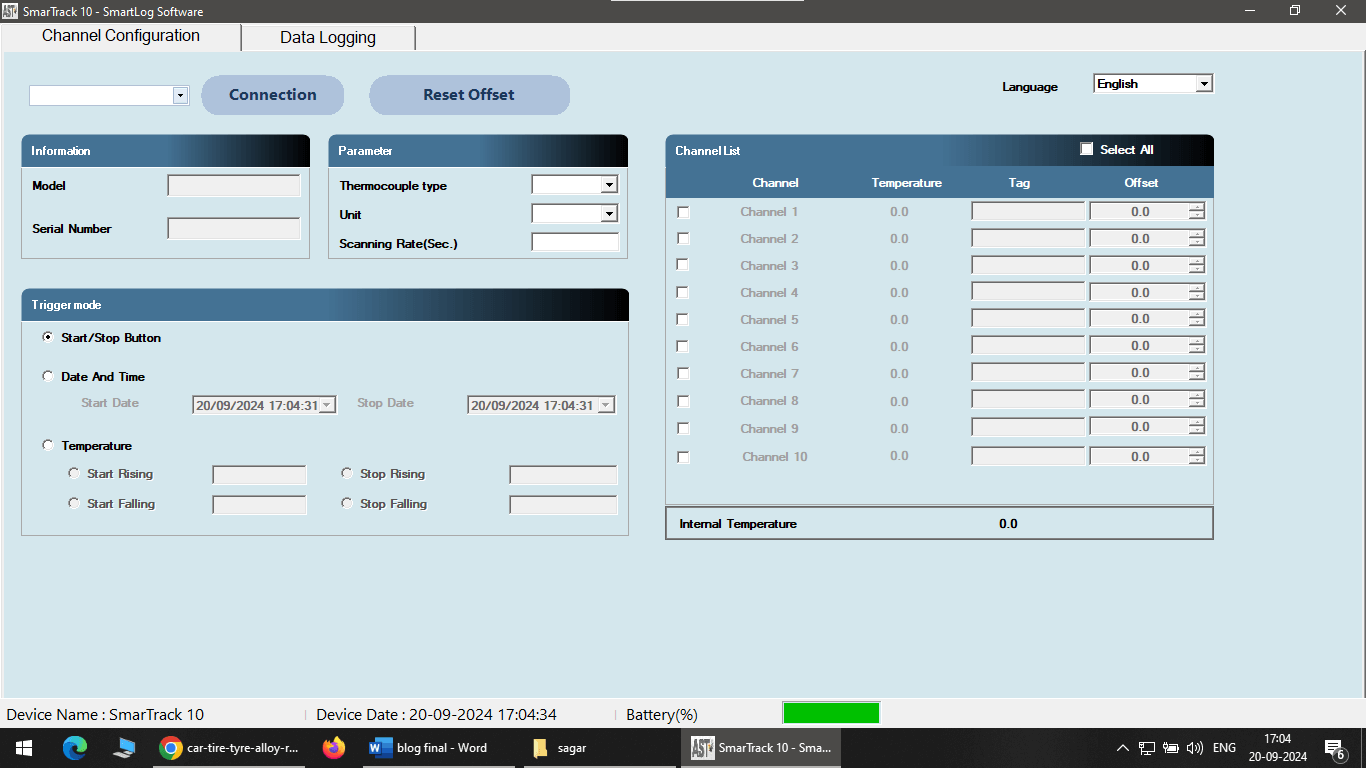

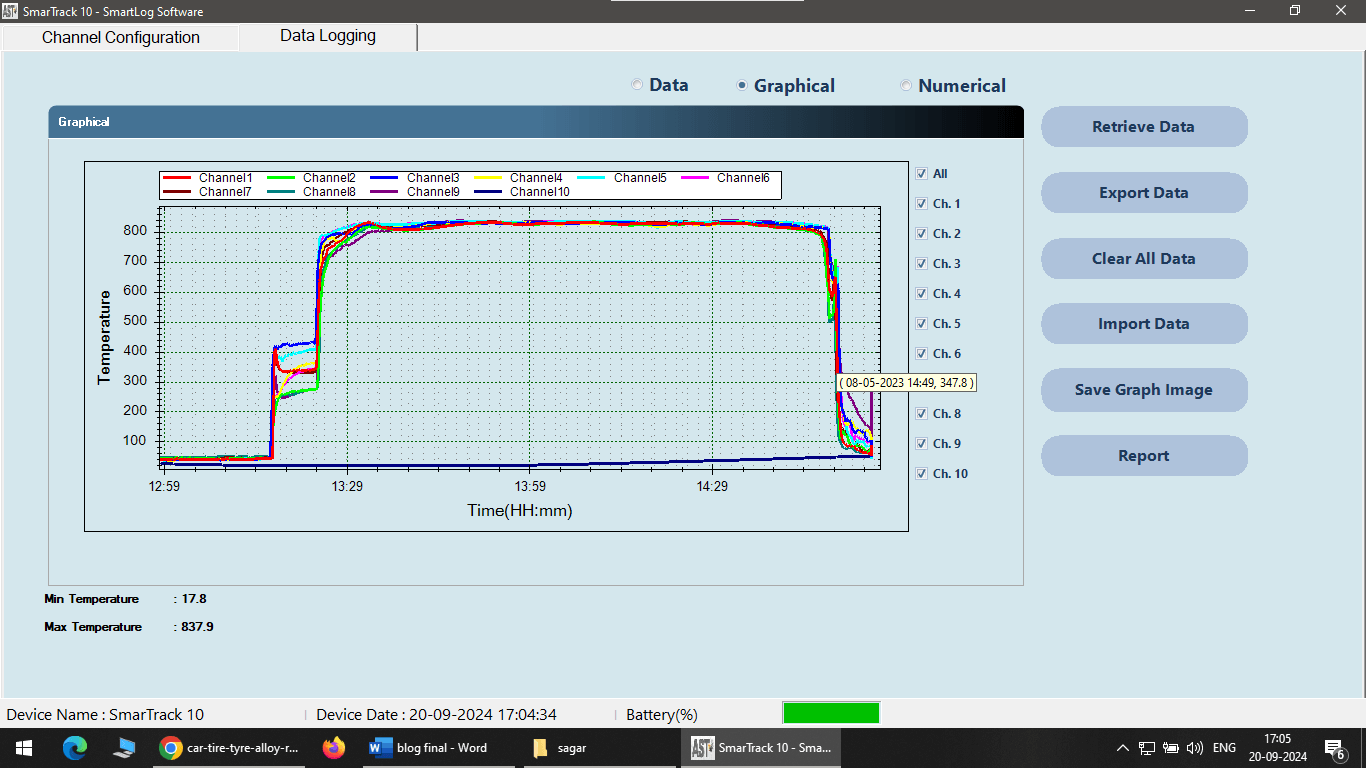

Aluminum heat treatment is an essential process that alters the physical and mechanical properties of aluminum alloys, improving their strength, hardness, and durability. This involves carefully controlled heating and cooling to achieve the desired material characteristics. Among the most commonly used techniques are T6 and T7 heat treatments, which include key steps like solution heat treatment, quenching, and aging. The T6 process consists of three main stages: The T7 process is similar to T6 but includes an additional or modified aging stage, designed to improve the stability of the material at higher temperatures, thus increasing resistance to stress and distortion. Both quenching and aging play a critical role in determining the final properties of aluminum alloys. If quenching is not done properly, it can lead to warping or residual stresses. On the other hand, correct aging ensures that the alloying elements precipitate correctly, contributing to the metal’s overall strength and hardness. Precise temperature control is crucial during heat treatment, especially during the quenching stage. Traditional methods often provide incomplete data, leading to potential errors. That's where the Thermal Profiling System from Tempsens comes in, offering a revolutionary approach to heat treatment processes. Tempsens' Thermal Profiling System features a Thermal Barrier Box (TBB-WQ-215), a data logger, and thermocouples, all working together to monitor temperature in real time throughout the T6 or T7 process.      Key Features: Tempsens also offers advanced thermal profiling software that provides deep insights into the heat treatment process. By monitoring the quench curve, manufacturers can ensure consistent cooling rates, reducing the risk of distortion, cracking, or residual stress. This accuracy helps achieve the desired mechanical properties, such as hardness and tensile strength, reliably. The Tempsens Thermal Profiling System, with advanced components like the TBB-WQ-215 thermal barrier box, ensures accurate temperature control, minimizing defects and maximizing the quality of the final product. Whether performing T6 or T7 heat treatments, adopting thermal profiling can significantly enhance efficiency, validate processes, and improve material performance.

What is a CNC machining center?

CNC machining center is composed of mechanical equipment and CNC system, suitable for processing complex parts of high efficiency automated machine tools, and the use of cnc control system to generate digital signals to drive the milling machine mechanism to do precision machining action, in layman's terms is the computer edited program is transmitted to the machine tool, control the machine tool automatically to a product processed out. Previously, ordinary milling machines are manually operated by the manual tool change and cutting, can only process some simple workpiece, and processing efficiency is low, and the quality is not high. And CNC machining center generally comes with tool magazine, are automated processing, including the elimination of Tang Xuan decoration work threads and cutting threads, etc., with a variety of processing work to go process means, comprehensive processing capabilities are very strong.

CNC machining or computer numerical control machining is a digital manufacturing technology, CNC machines can rotate around a different number of axes, tools are usually three or five axes. The basic CNC process can be divided into. An engineer first designs a CAD model of the part, and then a technician converts the CAD file into a CNC program called G-code. Machining Center,Vertical Turning Machines,Vertical Machining Center,Horizontal Machining Center Spindle Ningbo Yien Machinery Co., Ltd , https://www.yienmachinery.com

T6 and T7 Heat Treatment Processes

The Importance of Quenching and Aging

The Role of Thermal Profiling Systems in Heat Treatment

How Thermal Profiling Enhances Quenching and Aging

Benefits of Thermal Profiling

Software for Data Processing and Temperature Analysis

How Thermal Profiling Enhances Quenching Accuracy